Commissioning/ verification

The construction cycle of the building life cycle is the time when the design intent is translated into a physical reality. Given novel integrated systems with which contractors (vendors, installers, commissioning (Cx) agents, etc.) do not have much experience, there is a risk that carefully laid plans will go amiss. To insure that the automated shading and daylighting control systems were installed and operating as intended, the manufacturers, LBNL, and the Times Company developed procedures to commission and verify system performance. With verification data resulting from these procedures, the Times Company possessed the unique capability to measure and compare performance to design intent then discuss and tune system performance with the manufacturer prior to closure of the work scope and occupancy of the building.

Automated Shades

Larry Dumpert, The New York Times Company, using the shade commissioning cart at the Times Building.

Photo credit: LBNL

For the automated shading system, the critical aspect of the commissioning task was not simply to determine whether the various parts of the manufacturer's control were working; the system had to work per the performance specification and optimize competing performance tradeoffs. If the manufacturer's setpoints, delays, and other factors used to dampen control system response and reduce occupant distraction are too conservative, the shades will be down for the majority of the year, eliminating much of the daylighting and energy saving benefits to the interior. Therefore, the commissioning task focused on tuning the setpoints and delays so that the control system achieved a satisfactory balance between providing daylight and views out and mitigating window glare and direct sun.

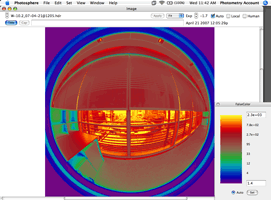

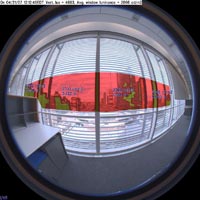

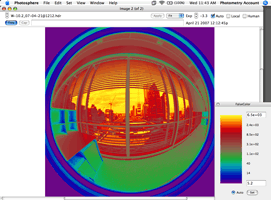

Example of results from shade commissioning cart. Top images shows shades in automatic mode where system passes because average window luminance is less than 2000 cd/m2 (actual 557 cd/m2). The shades are raised to determine if the shades should have been up because there was no need for glare control. Results of this second measurement (bottom images) show that the average window luminance exceeds 2000 cd/m2 (actual is 2866 cd/m2) so the shade again passes. Falsecolor luminance maps in right hand column images and pink area on left hand column images showing potential glare sources.

A new tool was built to measure average window luminance using high dynamic range (HDR) digital photography. The tool uses a computer and a conventional full-frame digital camera with a fisheye lens. The software computes the average luminance as well as detects potentially problematic glare sources that exceed 2000 cd/m2 with solid angles that are greater than 0.1 steradians. The total time to take one measurement is 3-4 minutes. Additional tools and procedures were created to help the user identify the correct control mode and troubleshoot problems in the field. With these verification data, the owner was able to hold firm, productive conversations with the manufacturer regarding inadequate control and to use the data to diagnose problems. See the Publications section for more information.

DALI Dimmable Lighting

For the daylighting control system, the work did not focus on defining procedures for commissioning the photosensors (tuning the gains and offset) and other components of control. Rather, the work focused on verifying that the systems worked after the manufacturer completed commissioning the photoelectric control system. Procedures were defined to determine whether the task illuminance setpoint was maintained under variable daylight and shading conditions, whether proportional dimming was occurring, and to ensure that underdimming did not occur. Similar to the balance in tradeoffs required by the shade control system, under-dimming (or over-lighting) ensures that task illuminance levels are adequate but defeats the intent of installing daylighting controls for saving energy. Given that dimmable daylighting control systems and commissioning guidelines have been available over the past two decades, the unique challenge was to develop new procedures given the capabilities of a DALI system.

Lighting commissioning cart (left) consisting of a 3x3 array of illuminance sensors placed on the work plane to monitor average illuminance over a 20 minute period. Ceiling pattern of dimmed fixtures (right) with window at the top of the photograph.

This process of iterative refinement of installation and calibration techniques in large buildings based on collection and analysis of on-site performance data is a significant advance over common practice. This work should be valuable for other owners who are considering such projects. See the Publications section for more information.

Underfloor Air Distribution System

The Times Company worked with The Center for Environmental Design Research to develop a commissioning cart for their underfloor air distribution system. More information can be found at: