Daylighting field study

As the building owner researches technology options, the usual questions surface that concern the purchase of any new product: how will it work for my application, are the vendor claims valid, what risks are incurred, and will the performance benefits be sustained over the life of the installation? Most designers and owners do not have ready access to answers to these questions, thus slowing innovation. The Times Company mockup test program was designed to accomplish several objectives: 1) enable vendors to not only prove the various features of their systems but also finetune their systems to meet the evolving requirements of the building owner, and 2) understand the benefits and limitations of each manufacturer's approach to shade management and daylighting controls.

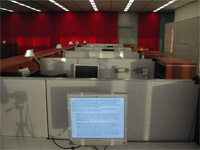

Interior views of the daylighting mockup in early December 2004.

Photo: Attila Uysal, SBLD Studio, Inc.

A 4500 ft2 mockup was constructed near the final building site and the southwest corner of the building tower was reproduced at full scale and fully furnished. The mockup was divided into two areas where two different roller shade manufacturers and two different manufacturers of dimmable lighting systems installed commercially-available systems in each area with different types of sensors and control strategies. The objective of the test was not to perform a side-by-side comparison of the two "competing" systems but rather to understand how vendor decisions regarding control infrastructure and design might impact actual field operation. The end goal of the monitoring phase was not the selection of one or another of the manufacturers' products in the mockup but rather the development of a detailed performance specification that would be open for bid by qualified vendors.

Lighting energy use, workplane illuminance and distribution, various parameters related to visual comfort, control operations, exterior solar conditions, and other environmental parameters were monitored continuously (1x/min, 24/7) in each area by either LBNL instrumentation or by the manufacturers' control systems. Area A of the mockup had only a western exposure while Area B of the mockup had both a western and southern exposure so the two data sets are not directly comparable. Monitored data were collected from December 21 to June 21 to capture the full range of solar conditions. Additional control options were studied from June 21 to September 21. During this time, the manufacturers were permitted to tune their systems to obtain optimal performance and improve their designs. The Times Company, upon seeing the effect of their initial control specifications, tweaked some control settings to obtain a system that better met their needs. In some cases, manufacturers altered their systems in response to interim performance data from LBNL indicating that the owner's specifications were not being met.

Sensor network in the daylighting mockup.

Photo: Vorapat Inkarojrit, LBNL